Choosing the best silk screen machine is one of the most important steps in building a reliable printing workflow. Whether you're launching your first creative space or upgrading a commercial setup, the right machine determines the clarity, stability, and repeatability of your prints. A well-selected system not only boosts output quality but also reduces wasted time, materials, and effort.

The current market offers a wide range of screen printing machines—from simple one-station presses to advanced all-in-one units equipped with exposure systems and modular color add-ons. This variety is beneficial, but it can also make the selection process overwhelming. Each machine is designed with specific users and workflows in mind, and matching those features to your goals is essential for long-term performance.

In this guide, you'll discover the defining qualities of a high-performing silk screen machine, how printing area and frame compatibility impact results, and what to look for when choosing between manual presses and more comprehensive systems. You’ll also find real examples from our catalog to help you understand how different designs function in real workshop conditions.

KEY POINTS:

- What defines the best silk screen machine for different types of workshops

- Differences between basic screen printing presses and advanced all-in-one systems

- How printing area, frame compatibility, and adjustment controls affect results

- What matters most when choosing equipment for multi-color or high-volume workflows

- Real examples of professional machines used in modern studios

Evaluating Essential Factors in a Silk Screen Machine

Choosing the right silk screen machine becomes far easier once you understand how specific features influence print quality and workflow efficiency. Whether you’re running a compact home studio or a small commercial space, your machine must provide stability, precision, and repeatable performance. Evaluating these core factors early helps prevent costly upgrades and ensures that your setup supports both current tasks and future expansion.

When reviewing potential machines, consider these key aspects:

- Printing area and the typical materials you plan to work with

- Frame compatibility, including both wooden and aluminum options

- Overall construction quality and stability through repeated cycles

- Adjustment controls for off-contact, tension, and registration

- Ease of setup, cleaning, and transition between print jobs

Tip: Prioritize machines with dependable, fine-tuned adjustments – they provide greater control and consistency when working with varying materials and complex prints.

By analyzing these elements proactively, you’ll gain a clear picture of which machines can support long-term use and more demanding production needs. This knowledge also helps you differentiate between basic presses and advanced systems capable of scalable, multi-color workflows.

Evaluating Different Types of Silk Screen Machines

Before selecting the best silk screen machine for your setup, it’s important to understand how different machine types impact flexibility, speed, and user experience.

Every workshop operates differently: some primarily handle shirts and textiles, while others print on mixed materials or require precise alignment for multi-layer designs. Your equipment must align with the type and frequency of projects you handle.

When comparing machine types, look at the following distinctions:

- Manual single-station presses for simple textile printing

- All-in-one systems with built-in exposure units for compact, streamlined workflows

- Multi-station or modular presses designed for multi-color alignment

- Lightweight presses for beginners versus heavy-duty systems for high output

- Machines capable of handling both rigid substrates and fabric-based projects

Tip: Choose a machine that fits your current workflow but also supports a broader project range as your needs evolve.

Understanding how each type operates allows you to decide whether you need a compact beginner-friendly unit, a modular system for creative flexibility, or a comprehensive machine that manages both screen preparation and printing.

Reviewing Popular Silk Screen Machines for Modern Workshops

Comparing machine features becomes much easier when you look at real equipment used in working studios. Below are two professional models from our catalog representing different approaches to screen printing – one offering an all-in-one workflow and the other delivering stable textile-focused performance. Reviewing them side by side helps you determine which better fits your goals.

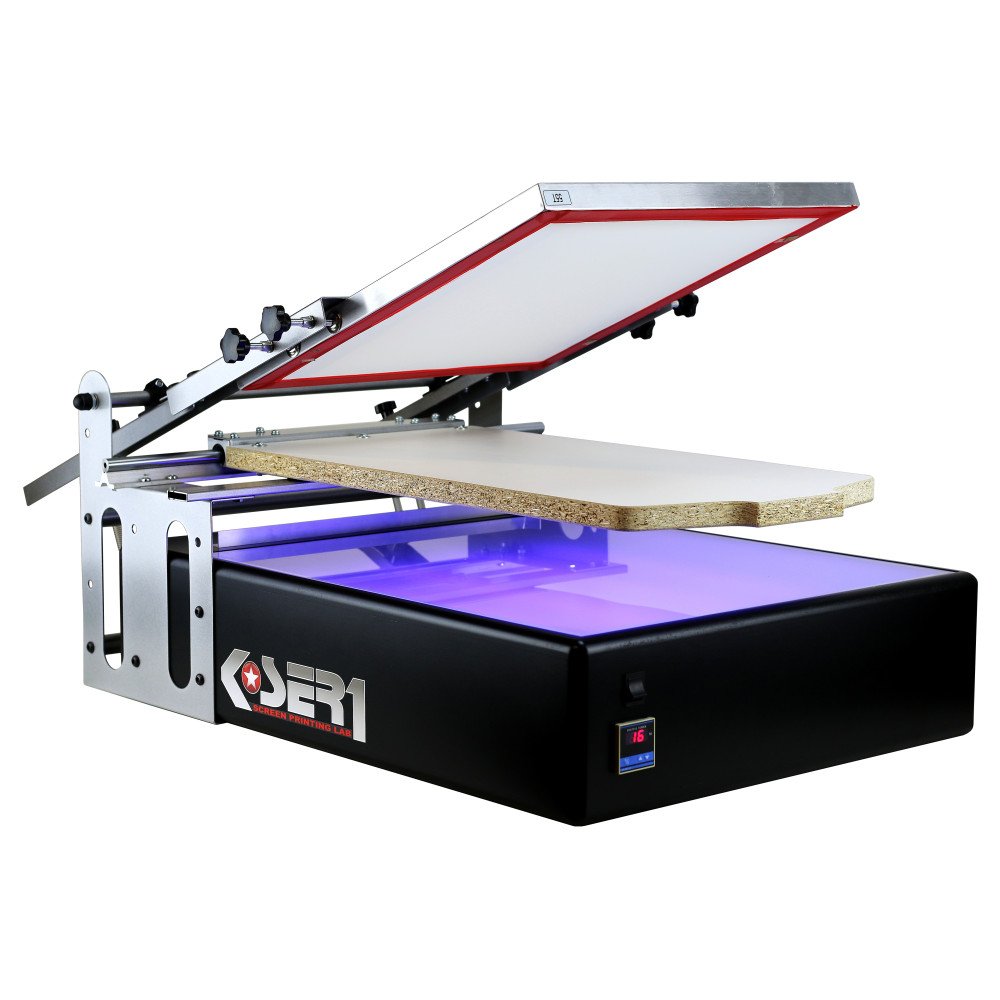

Screen Printing Machine K-SER 1 Evo

Screen Printing Machine K-SER 1 Evo – serves as a complete screen printing workstation, combining printing capabilities with an integrated UV exposure unit. Users can prepare screens, expose artwork, and print on a wide range of surfaces without additional external machines. Its generous printing area accommodates both textiles and rigid materials, making it an excellent choice for studios handling diverse projects.

Key features include:

- Integrated UV exposure lamps with a digital timer

- Large 40 × 60 cm printing area for textile and rigid substrates

- Capability to print on T-shirts, bags, wood, metal, plexiglass, and more

- Patented modular “slide system” for multi-color printing

- Complete starter kit with frame, squeegee, emulsion, and ink

Thanks to its modular design and all-in-one construction, the K-SER 1 Evo offers professional performance while staying compact. It provides capabilities similar to multi-station setups but with greater flexibility and a smaller footprint.

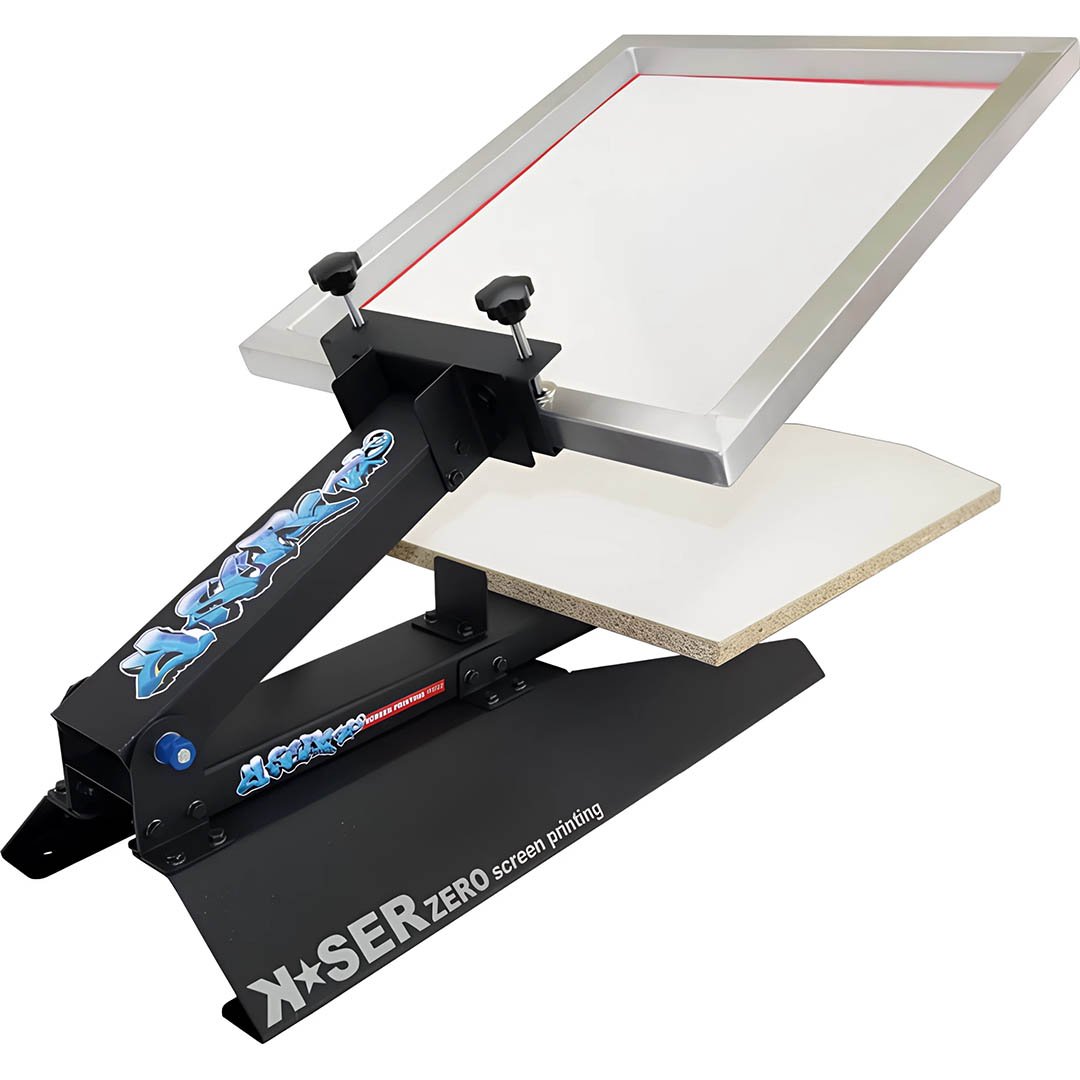

Screen Printing Press K-SER ZERO

Screen Printing Press K-SER ZERO – is a manual textile press engineered for consistent, high-quality garment printing. Its gas-spring support mechanism ensures smooth movement during printing, while the shaped printing surface allows for easy garment loading. Robust frame compatibility and ergonomic design make it suitable for small-to-medium workshops.

Key features include:

- Gas-spring support for steady frame operation

- 38 × 54 cm printing area suited for most garment projects

- Adjustable screws for varying frame thicknesses

- Compatibility with both wood and aluminum frames

- Designed and manufactured exclusively by Keygadgets

The K-SER ZERO is ideal for studios that primarily focus on textile production. Its stability, user-friendly adjustments, and durable construction make it a strong foundation for dependable daily printing.

Optimizing Your Workflow With the Right Silk Screen Machine

Selecting the best silk screen machine is not only about specifications – it’s also about how well the equipment integrates into your everyday workflow. Machines that reduce unnecessary manual adjustments or simplify screen changes make printing smoother, faster, and more predictable. Whether you’re working with single-color designs or multi-layer artwork, the right setup helps maintain efficiency even as production volume grows.

- How quickly you can change screens or adjust alignment

- Whether the printing area supports your most frequent projects

- How stable the printing surface remains during continuous runs

- Whether the machine maintains reliable registration for multi-color jobs

- How easily you can clean components between sessions

Tip: Machines that minimize repetitive adjustments save significant time and help maintain consistent print quality during high-volume tasks.

A machine that fits naturally into your daily routine gives you more control over output quality, reduces misprints, and maintains consistent performance as your workshop grows.

Optimizing Your Workshop Layout for Better Silk Screen Printing

A well-planned workspace can elevate your entire printing process. Even the best machine cannot compensate for a cramped or inefficient layout. An optimized environment ensures smoother material flow, reduces mistakes, and supports better concentration – all essential elements of a productive workshop, no matter the size.

- Dedicated areas for preparation, printing, and drying

- Stable surfaces to keep screens and tools within reach

- Proper lighting for alignment, inspection, and exposure

- Comfortable space for moving materials without interrupting the setup

- Adequate ventilation to support drying and maintain working comfort

- Organized storage for screens, tools, and inks

Tip: Build your layout with future growth in mind – a space that accommodates doubling your production will save time and prevent frequent rearrangements.

A thoughtfully arranged workspace doesn’t require large investments. Often, simple changes like improving lighting or reorganizing storage can dramatically improve your workflow.

Expanding Your Capabilities With Advanced Silk Screen Machine Features

As your workshop grows, your needs may extend beyond the basics. Many modern machines offer advanced features that allow you to expand your capabilities without replacing your entire setup. Understanding which upgrades matter will help you choose equipment that evolves with your skills.

- Modular color stations for more complex designs

- Built-in exposure systems for streamlined screen preparation

- Higher mesh compatibility for fine-detail printing

- Adjustable platen options for unique garment types

- Add-on accessories for rigid materials or specialty surfaces

Tip: Upgrading strategically – rather than all at once – helps maintain a balanced workflow without overwhelming your budget.

These advanced features can turn a standard printing setup into a versatile, scalable production environment.

Conclusion: Finding the Best Silk Screen Machine for Your Needs

Choosing the best silk screen machine comes down to understanding your workflow, the materials you work with, and the level of precision you expect from your equipment. By evaluating printing area, build quality, adjustability, and overall usability, you can avoid limitations that slow your growth and instead invest in a machine that supports both your current goals and your long-term ambitions.

As you explore different machine types, remember that there’s no universal model for every workshop. Some environments benefit from the versatility of an all-in-one unit, while others thrive with the stability of a dedicated press. The key is to select equipment that fits your production habits and provides room for future expansion.

If you're ready to upgrade your workshop, explore our Screen Printing Machines catalog and review models like Screen Printing Machine K-SER 1 Evo and Screen Printing Press K-SER ZERO. These professional tools provide a strong foundation for consistent, high-quality printing and long-term success.

Leave a Comment