Cold Laminators for Professional Use

The KeyGadgets cold lamination category features a curated selection of wide-format cold laminators and essential materials designed for clean, precise, and professional application. Our range includes manual and electric cold roll laminators built for handling posters, signage, vinyl graphics, and other large-format media where smooth film application and surface protection are critical. These devices ensure consistent results without heat, helping preserve print quality while preventing bubbling, distortion, and surface damage.

This category also includes compatible cold lamination supplies that support a complete production workflow, such as adhesive films and double-sided mounting sheets tailored for wide-format finishing. Together, this collection provides everything needed for reliable, high-quality cold lamination in studios, print shops, and professional workspaces - combining equipment and consumables into one streamlined selection for professional use.

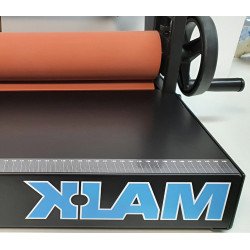

Manual Cold Roll Laminator Models

Manual cold roll laminator models offer reliable, wide-format film application for signage, posters, vinyl graphics, and other printed materials that require smooth, accurate lamination without heat. These devices provide controlled, hands-on operation, making them suitable for professional environments where precision and consistency are essential. By using a manual cold roll laminator, operators can apply protective film evenly across large surfaces while maintaining full control over pressure and alignment.

These models deliver practical benefits for everyday production tasks:

- smooth film application with minimal risk of bubbles or wrinkles

- compatibility with various cold lamination films and sheet materials

- stable construction designed for frequent operational use

- flexibility for studios, workshops, and print shops handling diverse formats

Thanks to their straightforward operation and dependable performance, manual cold roll laminators remain a preferred choice for businesses seeking efficient and cost-effective finishing equipment. They integrate seamlessly into existing workflows and pair well with cold lamination roller supplies where consistent, high-quality results are required.

Cold Laminator Roll Equipment

Cold laminator roll equipment is designed for consistent, high-quality application of protective films across wide-format prints, posters, adhesive sheets, and other materials that require a smooth, uniform finish. This category includes roll-based systems that support precise cold lamination without heat, ensuring accurate alignment and clean coverage across large surfaces. By using a cold laminator roll, operators can streamline daily production tasks and achieve stable, repeatable results in professional environments.

This type of equipment offers several practical advantages:

- compatibility with various cold lamination films and adhesive sheets

- smooth, controlled application suitable for wide-format media

- durable construction built for regular use in print and finishing workflows

- efficient handling of large materials, reducing manual effort

Cold laminator roll equipment is well-suited for studios, print shops, and production spaces that demand reliability, clean finishes, and predictable performance. It integrates easily with other cold lamination roller supplies, helping maintain a consistent workflow for everyday finishing tasks.

Cold Laminators for Sale

Our selection of cold laminators for sale is tailored for businesses that need dependable, wide-format finishing equipment and compatible lamination materials. The category combines professional-grade laminators with essential supplies, allowing users to build a complete setup for accurate cold film application. Each product is carefully selected to ensure consistent performance, clean results, and long-term reliability in production environments where precision is crucial.

Whether equipping a new workspace or upgrading existing tools, customers can find suitable solutions for everyday lamination tasks - manual and roll-based systems, adhesive films, and mounting sheets that work together to deliver stable, high-quality finishes. This makes the category a practical choice for studios, print shops, and service providers handling diverse wide-format materials.

For a streamlined purchase experience and fast delivery, explore our cold laminators and supplies and choose the options that best match your workflow needs. Order now to upgrade your lamination process with reliable cold lamination equipment.

FAQ

What is a manual cold roll laminator used for in professional printing and signage?

A manual unit is used to apply protective film to wide-format prints such as posters, signs, boards, decals, and other graphics that require a clean, uniform surface finish. It allows the operator to control pressure and alignment manually, ensuring accurate coverage without heat. This makes it effective for everyday production tasks where durability and visual clarity are essential.

How does a cold laminator roll help achieve smooth, bubble-free lamination on large graphics?

A roll-based system applies consistent downward pressure across the entire width of the material, which helps the film bond evenly to the surface. The steady rolling motion eliminates air pockets and minimizes wrinkles, allowing large graphics to be laminated with a smooth and professional finish. This method is preferred for wide-format applications where precision is critical.

How is a cold lamination roller used during the mounting and finishing process?

A handheld roller is typically used to press adhesive films or mounting sheets onto a substrate after initial placement. By moving the roller with controlled pressure, the operator removes air pockets and secures full contact between the materials. This tool is especially useful for final adjustments, edge adhesion, and detailed finishing where machine operation is not required.

Are cold laminators for sale suitable for applying adhesive films and double-sided sheets?

Yes. These systems are designed to handle a wide range of pressure-sensitive materials, including adhesive-backed films and double-sided mounting sheets. They provide the stability and even pressure needed to achieve a clean bond across large surfaces. This makes them suitable for both protective lamination and mounting tasks in production environments.

Which cold laminators deliver the best results for posters, vinyl graphics, and wide-format materials?

The most effective models are those that offer a stable frame, a smooth rolling mechanism, and compatibility with standard wide-format films. Units with adjustable pressure and a durable roller surface tend to produce the cleanest results on posters, vinyl, and similar materials. These features help maintain consistent quality across repeated production cycles.