Professional Pad Print Equipment for All Applications

Pad print equipment is essential for achieving clean, controlled image transfers across plastics, metals, glass, rubber, and a wide range of specialty surfaces. On this parent category page, you’ll find a complete selection of professional-grade tools and components designed to support every stage of the pad printing process. The assortment includes everything needed for precise results—from small custom runs to structured production workflows where accuracy and consistency matter most.

At KeyGadgets, the pad printing collection brings together equipment, materials, and consumables that form a reliable ecosystem for industrial, promotional, engineering, and creative applications. Each product is selected to provide stable ink transfer, clean print definition, and a smooth user experience for both beginners and experienced operators. With options built to match different production goals, this category makes it easy to assemble a dependable setup tailored to your printing needs.

High-Quality Pad Printing Products for Reliable Results

High-quality pad printing products play a central role in achieving clean, consistent image transfers across different materials and applications. This category includes a wide range of components that support precise ink handling, dependable print definition, and smooth workflow operation. Whether used in small studios or larger production environments, these pad printing products help maintain stable performance throughout the entire printing process.

Each setup benefits from essential elements designed to improve accuracy, ease of use, and long-term durability.

Key components often include:

- Specialized pads that ensure accurate ink pickup and transfer

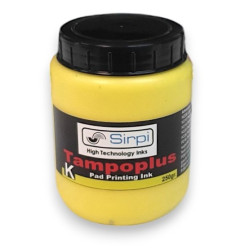

- High-performance inks formulated for various substrates

- Plates and clichés designed for sharp, detailed prints

- Cleaning and maintenance accessories that support consistent results

- Pad printing machines and kits

With these carefully selected components, users can build a reliable pad printing system optimized for repeatability and professional-grade output. This structure allows operators at any skill level to maintain high production standards without unnecessary complexity.

Pad Printing Material and Essential Components

Pad printing material plays a crucial role in ensuring accurate ink behavior, clean transfers, and stable performance throughout each printing cycle. The right combination of materials helps maintain consistent print quality, supports efficient setup, and enhances durability across a wide range of production tasks.

From detailed marking on small parts to larger industrial applications, these foundational components allow operators to achieve repeatable, professional results. Each pad printing setup requires properly structured materials that support smoother handling and precise image definition.

Common elements include:

- High-quality inks tailored to different substrates and production needs

- Transfer pads developed for controlled ink pickup and release

- Plates and clichés engineered for sharp, durable artwork impressions

- Compatible additives that stabilize ink flow and color performance

- Pad printing tooling accessories that support alignment and workflow efficiency

By integrating the right combination of materials and components, users can streamline daily operations, reduce print variation, and maintain dependable quality across numerous product types. This balanced structure ensures a stable working environment for both entry-level setups and high-volume production.

Pad Printing Tooling and Equipment for Sale

Pad printing tooling is a key component in building a stable, high-performance printing setup that supports precise alignment, smooth ink transfer, and efficient daily workflow. This category brings together essential tools and compatible equipment available for purchase, helping users maintain consistent production quality across various applications. Each item is selected to ensure dependable operation, durability, and compatibility with professional pad printing systems.

Whether you are upgrading an existing setup or assembling a new workflow from the ground up, this range of equipment and accessories offers solutions for both small-scale and industrial-level production. The selection includes options suitable for detailed part marking, promotional items, and specialized engineering projects, giving operators the flexibility to achieve clean, reliable results with minimal adjustment.

Choose the right components for your pad printing needs and build a setup that delivers long-term stability. Enjoy fast worldwide shipping and convenient access to high-quality tools designed to support professional-grade printing performance.

FAQ

What are the essential pad printing supplies for a complete pad printing setup?

A complete setup typically includes everything required to prepare, transfer, and maintain the print process, such as inks matched to the substrate, silicone pads suited to the desired level of detail, photopolymer plates prepared in a controlled exposure cycle, and solutions used for adjusting viscosity and cleaning equipment. When these components are selected together and calibrated correctly, the system performs predictably, allowing stable ink transfer and consistent output across repeated applications.

What types of pad print equipment are most commonly used for small and medium production?

For small and medium production runs, the most commonly used solutions are compact printing presses supported by reliable exposure units that prepare plates with precise relief depth. These machines offer a balance of speed, accuracy, and ease of operation, making them ideal for businesses that need repeatable alignment without the footprint or complexity of large industrial systems. Their design allows operators to handle various product shapes while maintaining consistent print quality throughout the batch.

What pad printing materials are recommended for making high-quality photopolymer plates?

High-quality plates rely on photopolymer sheets with uniform coating density, stable film positives that preserve fine detail during contact exposure, and a UV unit capable of delivering even illumination across the entire plate surface. When combined, these materials produce clean edges, controlled depth, and long-lasting durability, ensuring that the engraved image transfers ink with accuracy throughout extended production cycles.

What pad printing products are needed for consistent multi-color printing results?

Achieving reliable multi-color output requires compatible ink formulations, precisely prepared plates with accurate registration, and silicone pads that maintain uniform pressure across every print cycle. When these elements interact correctly, each colour lands exactly where intended, preventing shifts between layers and ensuring that gradients, small graphics, and detailed artwork remain clean and evenly defined from the first print to the last.

What pad printing tooling is required to achieve stable ink transfer and precise print alignment?

Stable ink transfer depends on well-maintained doctoring components, smooth ink cup operation, and support tools used to prepare and handle plates without distortion. High-precision alignment is achieved when these tools create consistent pressure and clean ink pickup, allowing the pad to move predictably and deposit the image in the exact location on each product, even during longer or repeated print cycles.