Cold Laminator Machines for Professional Laminating Tasks

Cold laminator machines are designed for precise and reliable lamination without the use of heat, making them suitable for a wide range of materials that may be sensitive to high temperatures. This type of equipment is widely used in printing workshops, advertising production, and finishing departments where smooth and bubble-free lamination is required. Cold lamination helps protect prints from moisture, dust, and mechanical damage while preserving color quality and surface details.

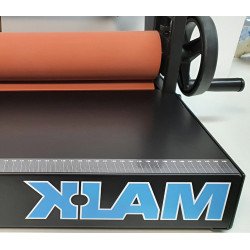

Cold Roll Laminator Machines are especially effective for large-format applications such as posters, banners, vinyl graphics, and self-adhesive films. The rolling system ensures even pressure across the entire surface, resulting in a professional finish and consistent output. These machines are commonly used for both commercial production and in-house finishing, offering a practical solution for businesses that need dependable laminating results.

Choosing the right laminating equipment allows users to improve workflow efficiency and product durability. Cold laminators provide a balance between performance, ease of use, and versatility, making them an essential part of modern printing and graphic production environments.

Advantages of Cold Roll Laminator Machines in Daily Use

Cold roll laminator machines are valued for their simple operation and high adaptability to different laminating tasks. They allow precise control over pressure and alignment, which is essential when working with various media types and thicknesses. A cold press laminator machine is particularly useful for applications where uniform pressure and surface protection are critical.

These machines are suitable for both small workshops and larger production spaces. When selecting cold laminator machine for sale, users benefit from equipment that combines durability with consistent performance.

Key advantages of this laminating technology include:

- Smooth and even lamination without heat exposure

- Compatibility with self-adhesive films and pressure-sensitive materials

- Reduced risk of material distortion or color changes

- Easy operation and low maintenance requirements

- Suitable for both large formats and small laminating machines setups

Cold roll laminators are an efficient solution for businesses looking to expand their finishing capabilities while maintaining high-quality standards. Their flexibility makes them a reliable choice for various professional laminating needs.

Applications of Cold Laminator Machines in Printing and Finishing

Cold laminator machines are widely used in printing, advertising, and finishing processes where high-quality surface protection is required. This equipment is suitable for laminating posters, photographs, banners, stickers, and printed graphics, ensuring durability and a professional appearance. Cold lamination is especially important for materials that cannot withstand heat, preserving both structure and color accuracy.

These machines are used in various production environments, from small workshops to professional print shops. Cold lamination provides consistent results across different materials and formats, making it a reliable solution for daily production tasks.

Common applications include:

- Laminating posters, prints, and photographic materials

- Finishing vinyl graphics and self-adhesive films

- Protecting printed surfaces from scratches, moisture, and UV exposure

- Preparing advertising materials for indoor and outdoor use

- Enhancing durability and visual quality of graphic products

Thanks to their versatility, cold laminators are an essential part of professional finishing workflows where precision and surface protection are required.

Buy Laminating Machines for Professional Use

If you are planning to buy laminating machines, this category offers a wide selection of reliable cold laminating solutions for professional applications. The range includes compact models for limited workspaces as well as larger machines suitable for high-volume production. Each solution is designed to deliver consistent lamination quality across various materials and formats.

Customers benefit from a diverse assortment, dependable equipment quality, and worldwide delivery options. Whether you need a basic solution or advanced laminating equipment, these machines are suitable for both beginners and experienced professionals.

Select the right laminating solution and place your order online to enhance your finishing capabilities with professional results.

FAQ

What are cold laminator machines used for in printing and graphic production?

They are used to protect printed materials by applying a pressure-sensitive film without heat. This process helps preserve color accuracy and surface quality while adding resistance to moisture, scratches, and everyday wear. Such equipment is commonly applied to posters, photographs, graphics, vinyl prints, and advertising materials that require a clean and professional finish.

How do cold roll laminator machines differ from hot laminating systems?

Cold systems rely on mechanical pressure rather than temperature, which makes them suitable for heat-sensitive materials. Hot systems use heated rollers and are more limited when working with delicate prints. Cold lamination offers greater flexibility, reduced risk of distortion, and simpler operation, especially in environments where consistent results are required across different media types.

What should be considered when choosing a cold press laminator machine for professional use?

Important factors include working width, pressure control, ease of alignment, and overall build quality. It is also essential to consider the types of materials being laminated and the frequency of use. Professional users often prioritize stable construction and precise adjustment options to ensure repeatable results in daily production.

Are small laminating machines suitable for workshops and limited workspaces?

Yes, compact equipment is well suited for workshops with limited space or moderate production needs. These machines provide reliable lamination quality while remaining easy to operate and store. They are commonly used for short runs, custom projects, and environments where flexibility and space efficiency are important.

Who should buy laminating machines designed for cold lamination processes?

This type of equipment is ideal for print shops, advertising studios, and production teams that regularly work with sensitive materials or require consistent surface protection. It is also a practical choice for businesses focused on customization, controlled workflows, and reliable finishing results without the complexity of heat-based systems.